The Versatile World of LDPE Film: Applications, Benefits, and Future Trends

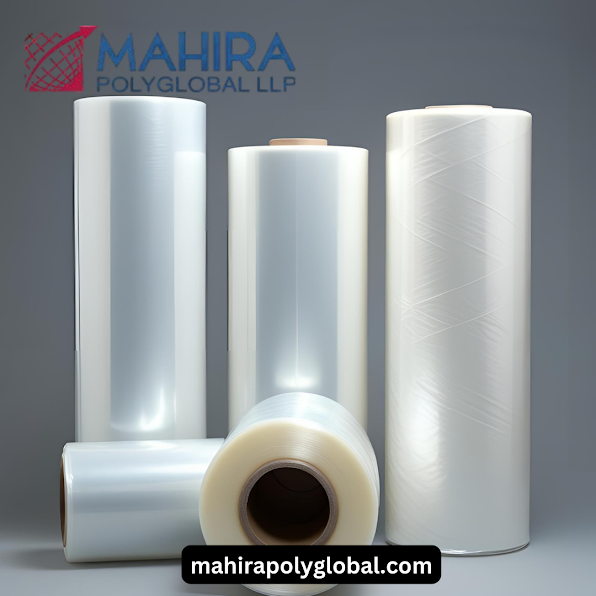

The Low-Density Polyethylene (LDPE) film has been an essential component across different sectors, particularly in packaging and industrial applications. The combination of its distinct characteristics; flexibility, durability, and chemical resistance, provides benefits to businesses looking to enhance product safety, presentation, and shelf life. The following Mahira Polyglobal LLP will outline the properties, advantages and applications of LDPE film, taking interest in shrink film rolls, LDPE shrink film and the role of LDPE shrink film manufacturers within the industry.

What is LDPE Film?

LDPE is a plastic made from the polymerization of ethylene - one of the mire common hydrocarbons found in natural gas. The polymers low density helps to create reasonable properties for both it's light weight, yet strong, flexible but tough. This combination offer a wide variety of great properties for many uses, the actual function of LDPE is unlimited! When made into a film LDPE provides excellent barrier for moisture, transparent, easy to print, and resistance to chemicals. This makes it a suitable candidate for packaging food products, consumer goods, and industrial goods. One of the more popular uses of LDPE film is shrink film which would take the shape of the products inside the package when heated. This helps keep the product safe during transport and visually appealing on the retail shelf. A common use for shrink film rolls is to bundle products together for shipping, providing extra precaution against damage during transit, as well as visually keeping a neat appearance.

The Benefits of LDPE Film

There are many benefits of LDPE shrink films for producers and consumers. One of the main advantages of LDPE is its extreme versatility. It can be manufactured in numerous thicknesses and configurations to produce specific packaging needs. This means the producer has the ability to create customized solutions for many products from irregularly shaped products to bulky products. LDPE film is also cost-effective and lightweight, therefore, reducing the final cost of packaging while utilizing space. The light weight of LDPE film can lead to lower shipping expenses, creating efficiencies for the company's logistical processes. Additionally, LDPE film is waterproof, oil resistant, and chemical resistant, which helps protect their products and extends shelf life, critical for perishable products. A primary advantage of LDPE shrink film is its transparency. This quality gives consumers the ability to see the product inside the package to enhance its marketability. As a consumer, clear packaging can depend on the product. In a retail environment, clearly packaged products can affect consumer buying decisions as consumers can see the quality and safety of the product.

How LDPE Shrink Film Works

There are many benefits of LDPE film for producers and consumers. One of the main advantages of LDPE is its extreme versatility. It can be manufactured in numerous thicknesses and configurations to produce specific packaging needs. LDPE film is also cost-effective and lightweight, therefore, reducing the final cost of packaging while utilizing space. The light weight of LDPE film can lead to lower shipping expenses, creating efficiencies for the company's logistical processes. Additionally, LDPE film is waterproof, oil resistant, and chemical resistant, which helps protect their products and extends shelf life, critical for perishable products. A primary advantage of LDPE shrink film manufacturers is its transparency. This quality gives consumers the ability to see the product inside the package to enhance its marketability. As a consumer, clear packaging can depend on the product.

The Role of LDPE Shrink Film Manufacturers

LDPE shrink film manufacturers serve as point-of-production and supply chain for LDPE films that provide high-quality films to the market for varied uses. The manufacturers of shrink film for LDPE offer an essential service in the production of LDPE films and shrink films by ensuring that the films are produced as required or exceed industry-recognized expectations. LDPE films must have different industry standards for safety, product quality, and innovativeness. There is an emphasis on quality of packaging materials and many of the leading manufacturers of LDPE shrink film invest significant money into Research and Development (R&D). They want to make sure the films they produce not only meet the market requirement of today but anticipate requirements for tomorrow. And while many manufacturers of shrink films follow eco-responsible practices, many of the large plastic film manufacturers incorporate research into recycled materials, biodegradable additives, and, of course, product responsibility or according to their customer's product responsibility and impact on sustainability and environmental impacts. Importantly, manufacturing quality LDPE films and shrink films is a business of customization. Businesses work with manufacturers to customize their solutions, whether they need custom sizes, printed films, or a thickness of films to meet their unique packaging needs.

Advancements and Innovations in LDPE Film Technology

Advancements in LDPE film technology are underway as the packaging industry continues to evolve and unfold. New additives and new methods of production are being examined by manufacturers, enabling them to be innovative as they enhance the capability of LDPE films. An example of innovation is using liquid-crystal displays that change color with variation in temperature to signal freshness, that can attract health-conscious consumers. Environmental accountability has also prompted developments for LDPE films, such as biodegradable alternatives, or compostable alternatives, that can maintain the benefits of plastic, while addressing the current environmental issues caused by plastic waste, and act as part of the global initiatives for sustainability. When consumer preferences shift towards the environment, the manufacturers track through the performance lens will be more dominant in the market.

Conclusion: The Future of LDPE Film in Packaging

In summary, Shrink wrap manufacturers, especially in its shrink film variant, presents an effective packaging option that combines practicality with visual appeal. Its flexibility, strength, and suitability for diverse applications make it a popular choice in sectors ranging from food and beverages to consumer products and industrial uses. As manufacturers of LDPE shrink film strive for innovation while focusing on sustainability, the outlook for this material appears bright, offering solutions that cater to both customer needs and environmental considerations. As companies adapt to the evolving landscape of packaging alternatives, LDPE film is set to remain integral to their strategies by ensuring efficient logistics and boosting brand recognition. By taking advantage of the properties of this adaptable material, businesses can satisfy market demands while upholding responsible practices.

Frequently Asked Questions (FAQs)

What is the main advantage of using LDPE shrink film?

The primary advantage of LDPE shrink film is its ability to provide a tight, protective seal around products when heat is applied. This feature enhances product protection, shelf life, and aesthetic appeal, making it an excellent choice for packaging.Can LDPE shrink film be customized?

Yes, LDPE shrink film can be customized in terms of size, thickness, and printing options. Manufacturers can work with businesses to create tailored solutions that meet specific packaging requirements.Are there eco-friendly options for LDPE shrink film?

Many LDPE shrink film manufacturers are now adopting sustainable practices, including producing biodegradable versions and incorporating recycled materials to minimize environmental impact.How does the cost of LDPE film compare with other packaging materials?

While the initial cost of LDPE film can be higher than some traditional packaging materials, its durability, versatility, and potential for reducing shipping costs can result in overall savings for businesses.

.png)

.png)

Comments

Post a Comment